Geonics Calibration Procedures

Geonics equipment does not go through a yearly factory calibration process. However, most of Geonics equipment needs to be fine tuned, calibrated, or checked occasionally to ensure quality data.

The lessons below will outline some common procedures to ensure that the user’s instrument is functioning properly. These lessons are general guides and not meant to take the place of instructions directly from Geonics. Remember to always consult the instrument’s user manual to ensure proper procedures as instrumentation configurations and calibration can change over time.

Some common suggestions before performing the calibration tests:

- Make sure the instrument’s batteries are charged. If not, replace them. Rechargeable batteries often need 12 hours to be fully charged. If using disposable batteries, purchase replacement batteries.

- Let the equipment warm-up for 10-15 minutes. If users calibrate the equipment right away without letting the equipment warm-up, there is a chance that rapid battery decay will skew results.

- Read the manual. Some instrumentation can be calibrated with the data logger. However, it is important to understand how to manually adjust the instrumentation without it.

- Have tools handy. Most of the instrumentation requires adjusting a fine or course lock screw. This means having a small crescent wrench to unlock the lock-nut and a small flat-head screw drive to make fine adjustments.

- Find an area free of metal or other environmental noise. This includes any metal on your person. it’s easy to forget to remove your keys and phone. Never wear steel-toe boots.

- Although weather, battery discharge, and humidity may alter readings, it’s always a good idea to have a bay station free of metal to compare and potentially adjust for drift.

- Perform nulling or calibration procedures any times conditions change. This could be at the start of a new day, change of battery or cables, severe weather conditions, etc.

- Keep good notes. Writing down what occurred during calibration or in the field can mean the difference between having to reacquire data and finishing a job.

EM38 Calibration and Function Tests

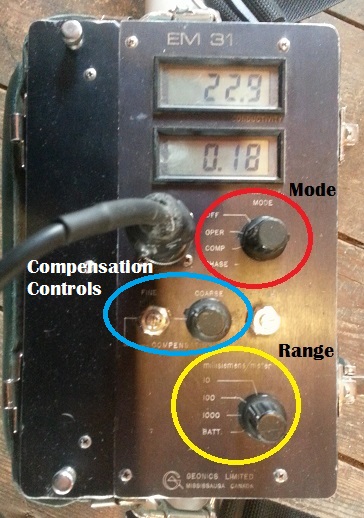

EM31 Calibration and Function Checks

EM34 Periodic Daily Checks

EM61-MK2A Odometer Calibration

For a comprehensive look at EM61 function tests please visit: