Geonics EM61 Suggestions and Common Problems

Geonics EM61-MK2

EM61 Configurations

The EM61 is a high power, highly sensitive four channel time-domain metal detector that detects ferrous and non-ferrous metal by sending out a primary magnetic field that creates a voltage, which in turn produces a secondary magnetic field. The EM61 measures the decay of this secondary magnetic field at different time gates to detect metallic targets. The EM61 is commonly used to find UXOs (unexploded ordnances,) environmental hazards such drums and underground storage tanks, construction and industrial waste, and utilities.

EM61 Configurations:

The EM61 comes in a number of configurations.

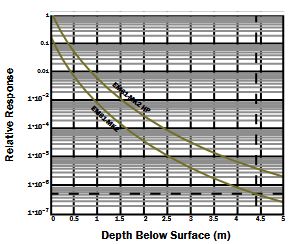

EM61-MK2/A: Originally, Geonics LTD produced the EM61-MK2, which required the user to wear a backpack that holds the instrument’s electronics and battery. Some found this too cumbersome so Geonics produced the EM61-MK2A that holds the electronics on the handle and the battery in the center of the bottom coil. Both configurations are still available to rent. Most users prefer the configuration without the backpack; however, some users anecdotally believe the backpack versions is more stable and possesses less instrument induced noise. Both units’ maximum depth of detection is approximately 5.5 meters or approximately 18ft, depending on the target’s composition, size, and orientation.

EM61HP-MK2 (high power): The EM61-MK2 HP is a modification that increases the depth of investigation by increasing the signal eight-fold, thereby drastically improving the signal to noise ratio. Depending on the target’s characteristics, this means that the depth of detection will increase between 45 and 80%.

EM61HH-MK2 (hand-held): The EM61-MK2 Hand-Held uses the same battery and electronics backpack as the EM61-MK2 but connects to a small 17 centimeter diameter coil on a staff. The staff can be held by the user with a shoulder strap or at a static elevation via trailer kit. The Hand-Held provides increased sensitivity to smaller targets at shallow depths while reducing more cultural noise. The EM61-MK2 Hand-Held can also be useful in very dense brush and rough terrain where the use of wheels is not possible.

Other configurations:

The EM61-MK2, EM61-MK2A, or EM61-MK2 High Power electronics can be used with either a top and bottom coil or just a bottom coil with a shorting plug. If the EM61 possesses both top and bottom coils, the unit can be run in four channel (4) mode or in the differential (D) mode. If the EM61 only possesses the bottom coil with shorting plug then only the four mode can be used.

In four channel mode, the instrument records four time channels measured by the bottom coil. In the differential mode, the instrument records three channels from the bottom coil and one channel from the top coil that can be used in post-processing for target depth calculations and suppression of near surface response.

Upon request, a stretcher can be used in place of a trailer kit (wheels) for any EM61-MK2 or EM61-MK2A. This requires two operators to carry the instrument since one person needs to hold the front handles and another needs to carry the back handles.

The EM61-MK2 and EM61MK2A can be tethered together in a towed array with one master unit and two slave units. This can allow the user to cover more land area quicker

EM61 Site Considerations

Environmental noise such as radar installations, TV and radio towers, power lines, and nearby metal objects will interfere and skew EM61 data acquisition. In some situations, it can make collecting data impossible. Personal objects such as keys, pocket knives or tools, cell phones, steel toe boots, etc are also common sources of noise that need to be moved from the operator’s person.

Once an area free of noise is determined, the operator is going to perform various instrument checks such as the cable shake test, static background test, and other functionality controls. As with all electromagnetic equipment, it is important to let the instrument warm up so that any initial battery decay does not affect the quality control checks.

Lengthy discussions on the function checks can be found by visiting the Geonics EM61-MK2 Quality Control Procedures page. In addition, it is important to follow any and all guidelines set forth in Geonics EM61 operator manuals. It may be a good idea to mark the area where the instrument checks are completed as a base station that is safe to conduct quality control tests.

Please note that if more than one EM61 unit or any other electromagnetic instrument is used in the same vicinity that there will be noise and the users should use extreme caution that they are not sensing signal from the other units.

Power and Battery Problems

The EM61-MK2, EM61-MK2A, and EM61-MK2 Hand-Held are all powered by the standard EM61 battery pack. Inside the EM61 battery shell is a 12v battery with a 9 to 12 amp hour battery. The instrument is supplied with two battery packs.

A fully charged battery will read above 13 volts while a completely discharged battery will read below 10.5 volts. Each fully charged battery should provide about 4 hours of continuous operation. Completely charging a fully discharged battery takes 14 hours.

The EM61 is temperamental to battery discharge rates and unsteady battery decay can make the unit nosier when the strictest noise parameters are needed for sensitive targets. Even brand new batteries off the shelf can present problems at times.

The EM61_MK2A High Power can use two types of batteries. The first battery type is the standard EM61 battery pack. With this battery, the unit can only be operated at lower power for 4 hours or high power for about 30 minutes. A larger capacity battery (24 amp hour) can also be used for standard power or high power output with the EM61-MK2 High Power. This battery will supply power for 10 hours in the low power mode and 2.5 hours in the high power mode. It is important to note that the larger capacity battery weighs over 22lbs compared to 10lb weight of the standard battery.

Remember to always allow any electromagnetic instrumentation to warm up for a minimum of 10 minutes before calibration. Battery decay during initial power-up will cause inaccurate calibration values.

Grid or GPS:

EM61 surveys can be performed in a number of ways. The most common are grid or with a GPS. When a grid is set up, EM61 readings are usually taken manually on lines in station increments with a trigger button either on the electronics or data logger cable. The user must physically push a button to record a reading and advance to the next station and trigger another reading and so forth. Lines can be set up one way or bidirectional depending on survey size and preference. Measurements can also be taken via Wheel mode in which the odometer will take a measurement at a predetermined increment.

A good rule of thumb is that it takes the same amount of time to set up a grid as in does to perform the survey. In many cases, it is useful to take GPS locations at the corners or the grid and points of interest such as corners, obstructions, etc.

EM61 surveys can also be done in Auto mode with a GPS. In this mode, the EM61 will take predetermined incremental measurements and tie a GPS location to the reading. It is important to consider the amount of EM61 data and GPS data needed given the speed at which the user travels. A reading per second is often recommended. Too much data can be cumbersome while too little data may not be sufficient. When possible, break large survey ares into smaller files in case a particular area needs to be resurveyed.

Common EM61 Problems and Solutions

The instrument won’t log.

- Is the instrument turned on? Check the fuse push button. Is it pushed in or is the fuse popped out? If out, push it in. If using a single EM61, is the Master/Slave switch set to Master?

- Is the battery fully seated and connected? The standard EM61 battery pack has three thumb screws that need to be tightened. The power cable to the battery and electronics is keyed and the collar on both ends needs to be fully secured.

- Is the battery pack fully charged? Check the voltage? Replace the battery if needed.

- Does the battery have a bad cell? Occasionally, batteries will develop a bad cell. The voltage read by an external volt meter will show full charge but the battery won’t perform under a load (when the instrument is turned on.) Often, this can be determined by erratic readings during the static background test or by turning the electronics’s volume all the way up and listening to the instrument’s hum. A surging sound indicates the battery’s voltage is unstable; often a sign of a bad cell. Replace the battery if needed.

- Is the instrument connected via data cable? Are the connections fully seated at both the data logger and instrument?

- Is the data logger cable connected to the assigned Com Port in the Logger Setup menu? Is there a conflict between the assigned data logger com port and assigned GPS com port?

- Is there a bad cable? Did the user try replacing cables one at a time with the spare to rule out a bad connection?

- Is the instrument enabled in the Logger Setup menu?

- Did the user create a data file and select “Go”?

- If using the NAV program, does the user have GPS signal? The instrument won’t log data in the NAV program if there is no GPS signal.

- Did the user try powering the instrument and data logger off and turning it back on?

- If all the above looks correct, the instrument’s data logging INI file may be corrupted. Locate this initialization file and delete it. This file is often in a folder called GEOINI and will have the same name as the logging program followed by the extention “.ini” When this file is deleted, it will reset the data logging program to defaults and all modifications that were changed before the survey will need to be changed again.

The instruments readings are unstable, do not change, or do not make sense.

- Are the batteries of sufficient power? Did the batteries get a full 14 hours of charge? Check the voltage. Replace batteries if needed.

- Does the battery have a bad cell? Occasionally, batteries will develop a bad cell. The voltage read by an external volt meter will show full charge but the battery won’t perform under a load (when the instrument is turned on.) Often, this can be determined by erratic readings during the static background test or by turning the electronics’s volume all the way up and listening to the instrument’s hum. A surging sound indicates the battery’s voltage is unstable; often a sign of a bad cell. Replace the battery if needed.

- Are the cables secure? Did they pass the cable shake test? Swap out data logger, power, and coil cable individually to isolate problem.

- Is there environmental noise that could affect the instrument’s readings? Is there another source of electromagnetic noise? Sometimes the only way to determine environmental noise is to pack up the instrument , move 5 miles, reset up the equipment, and see whether the user gets the same response.

- Does the instrument react to metal objects? Use a test object to see the response. If the EM61 possesses a QC coil, reference the Geonic’s user manual, and determine whether the instrument is receiving the correct response.

- Verify that the EM61 is set to the intended mode of collection; Is it in Auto, Wheel, or Manual mode?

- Are the anomalies too similar to the subsurface or small to detect?

- If all the above looks correct, the instrument’s data logging INI file may be corrupted. Locate this initialization file and delete it. This file is often in a folder called GEOINI and will have the same name as the logging program followed by the extention “.ini” When this file is deleted, it will reset the data logging program to defaults and all modifications that were changed before the survey will need to be changed again.